PET Bottle Flake Granulation Line

PET Bottle Recycling Pelletizer PET Granulation Machine Process Guda

Ƙayyadaddun Fasaha

|

Sunan Inji |

PET Single dunƙule Extrusion pelletizing Line |

|

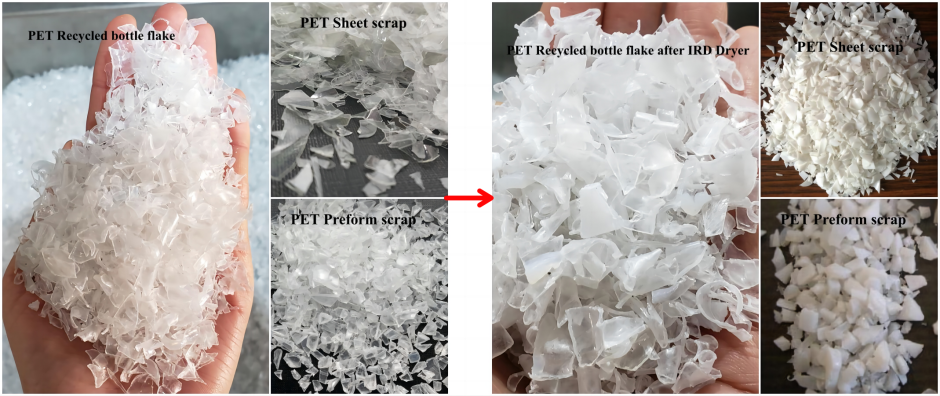

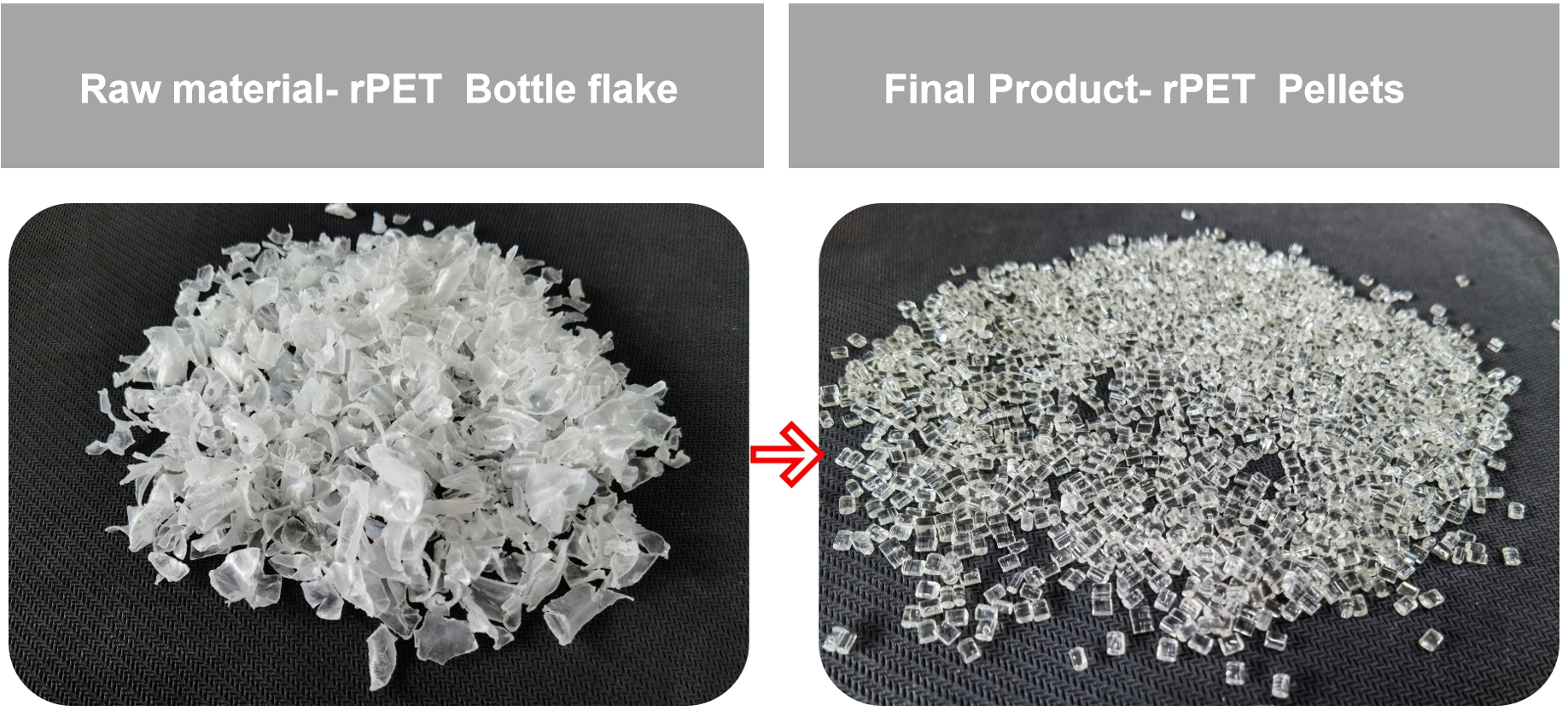

Albarkatun kasa |

Farashin rPET |

|

Samfurin Karshe |

Farashin rPET |

|

Abubuwan Layi na samarwa | Tsarin bushewar infrared crystal: Vacuum feeder/Infrared crystal dryer/Vacuum discharger

Single Screw Extrusion granulating line: Single dunƙule babban extruder/Hydraulic Double Pistons allo mai canza allo/Die head/Flushing trough water/Flushing pellitizer/Pertical dewatering machine/Vibrating sieve machine/Ajiya

|

|

Diamita na dunƙule |

90mm-150mm |

|

L/D |

1:24/1:30 |

|

Kewayon fitarwa |

150-1000KG/H |

|

Kayan dunƙulewa |

38CrMoAlA tare da Jiyya na Nitrding |

|

Nau'in Pelletizing |

Fitar da ruwa & pelletizing |

|

Mai canza allo |

Mai Canjin allo na Na'ura mai Ruwa Biyu Pistons |

Cikakken Injin

Infrared Crystal Dryer (LIANDA PATENT DESIGN)

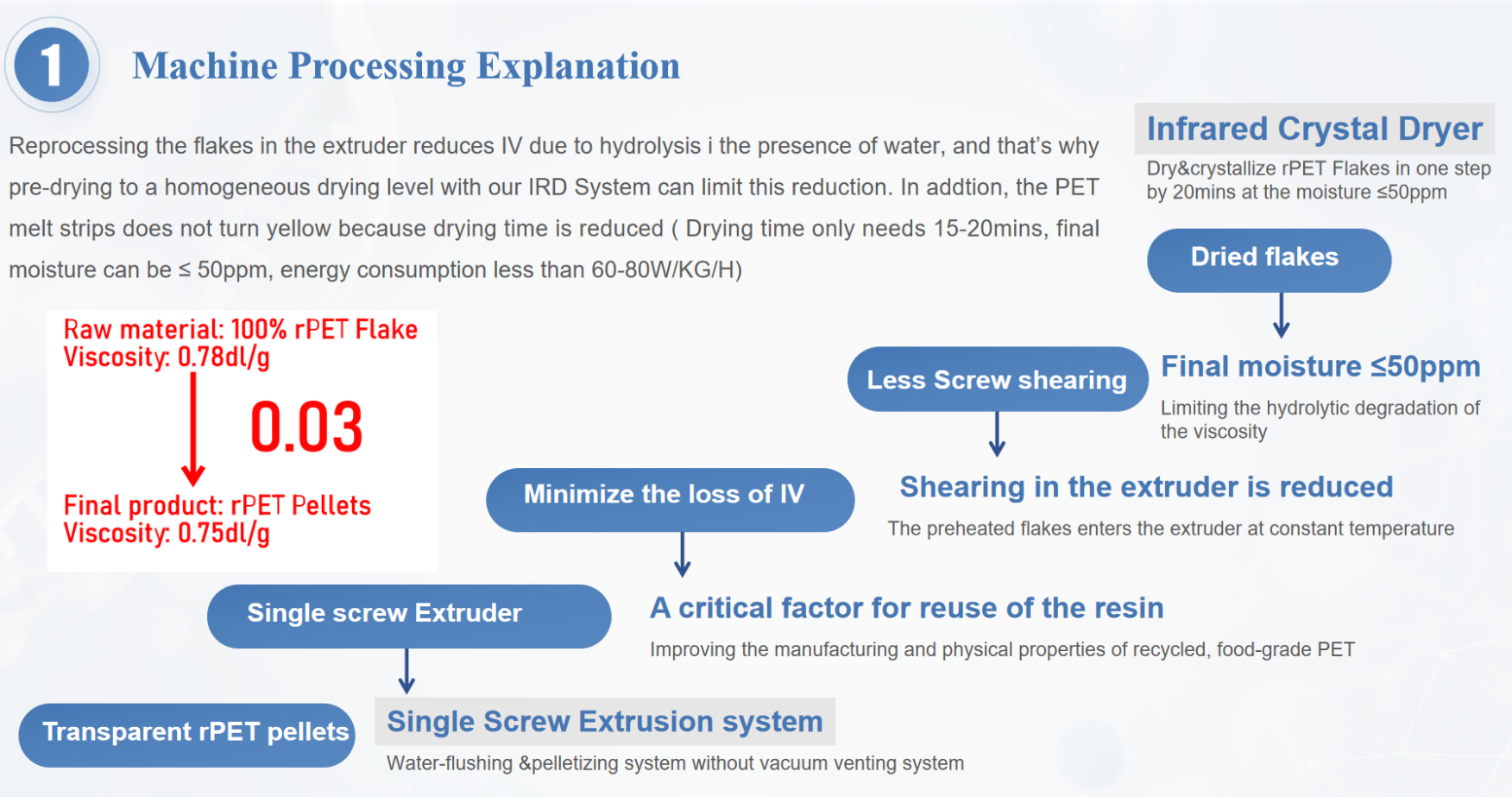

① Haɓaka masana'anta da kaddarorin jiki na sake yin fa'ida, PET-matakin abinci ta hanyar fasahar da ke da ƙarfi ta hanyar igiyar ruwa tana da muhimmin sashi don takawa a cikin kaddarorin danko (IV).

Pre-crystallization & bushewar flakes kafin extrusion yana taimakawa rage asarar IV daga PET, muhimmin mahimmanci don sake amfani da resin.

③Reprocessing flakes a cikin extruder rage IV saboda hydrolysis a gaban ruwa, kuma shi ya sa pre-bushewa zuwa kama bushewa matakin da mu IRD System iya iyakance wannan rage.

Bugu da kari, PET narkewa tube ba ya juya rawaya saboda bushewa lokaci ya rage (lokacin bushewa kawai bukatar 15-20mins, karshe danshi iya zama ≤ 30ppm, makamashi amfani kasa da 60-80W/KG/H)

④ Shearing a cikin extruder kuma an rage shi da shi saboda preheated kayan shiga cikin extruder a akai-akai zazzabi"

⑤ Inganta fitar da PET Extruder

Ana iya samun haɓakar girma mai yawa ta 10 zuwa 20% a cikin IRD, yana haɓaka aikin ciyarwa a mashigar extruder sosai - yayin da saurin fitarwa ya kasance baya canzawa, akwai ingantaccen aikin cikawa akan dunƙule.

Layin Pelletizing Extrusion Single Screw Extrusion (Ba tare da Vacuum Venting ba)

Yin amfani da ƙarfin Single dunƙule extruder da kuma daidaita shi tare da LIANDA na musamman tsara dunƙule don rPET kwalban flakes, mun sami damar ƙara iya aiki da 20% tare da m ikon cinye idan aka kwatanta da Parallel biyu dunƙule extruder.

Dankowar rPET pellets da tsarinmu ya samar: akwai kawai ≤0.02-0.03dl/g digon danko --- ba tare da ƙara kowane mai haɓaka danko ba. (A cewar gwajin mu na cikin gida)

rPET pellets Launi: m --- ba tare da ƙara kowane mai haɓaka bayyana gaskiya ba

Ba tare da tsarin iska ba --- Ajiye farashin makamashi, rashin matsala da kwanciyar hankali

Hotunan Inji