PET Granulating Line

Infrared Crystallization Dryer don rPET Extrusion granulating line

Infrared Pre-Bushewa na rPET Bottle Flakes: Haɓaka Fitarwa da Inganta Inganci akan PET Extruders

Bushewa shine mafi mahimmancin mahimmanci guda ɗaya a cikin sarrafawa.

>> Haɓaka masana'anta da kaddarorin jiki na sake yin fa'ida, matakin abinci na PET ta hanyar fasaha da ke da ƙarfi ta hasken infrared yana da muhimmin sashi don takawa a cikin kaddarorin danko (IV).

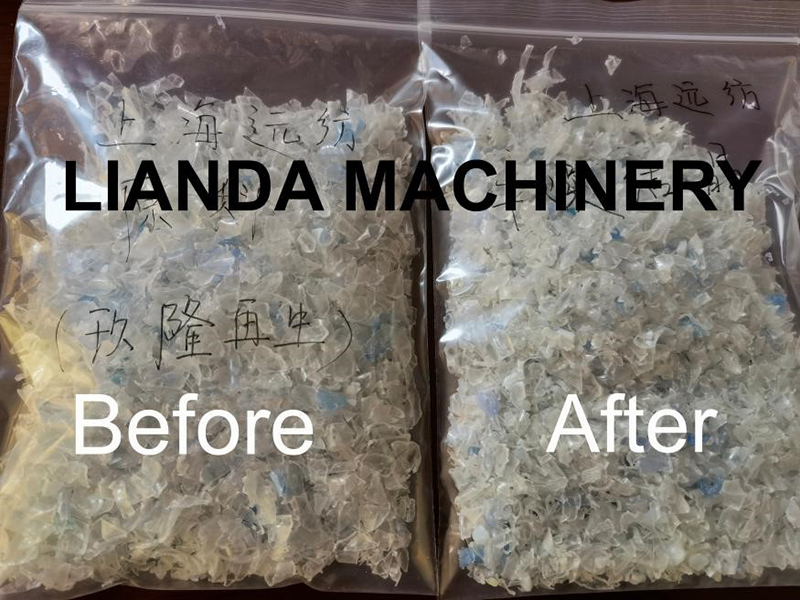

Pre-crystallization & bushewar flakes kafin extrusion yana taimakawa rage asarar IV daga PET, muhimmin mahimmanci don sake amfani da resin.

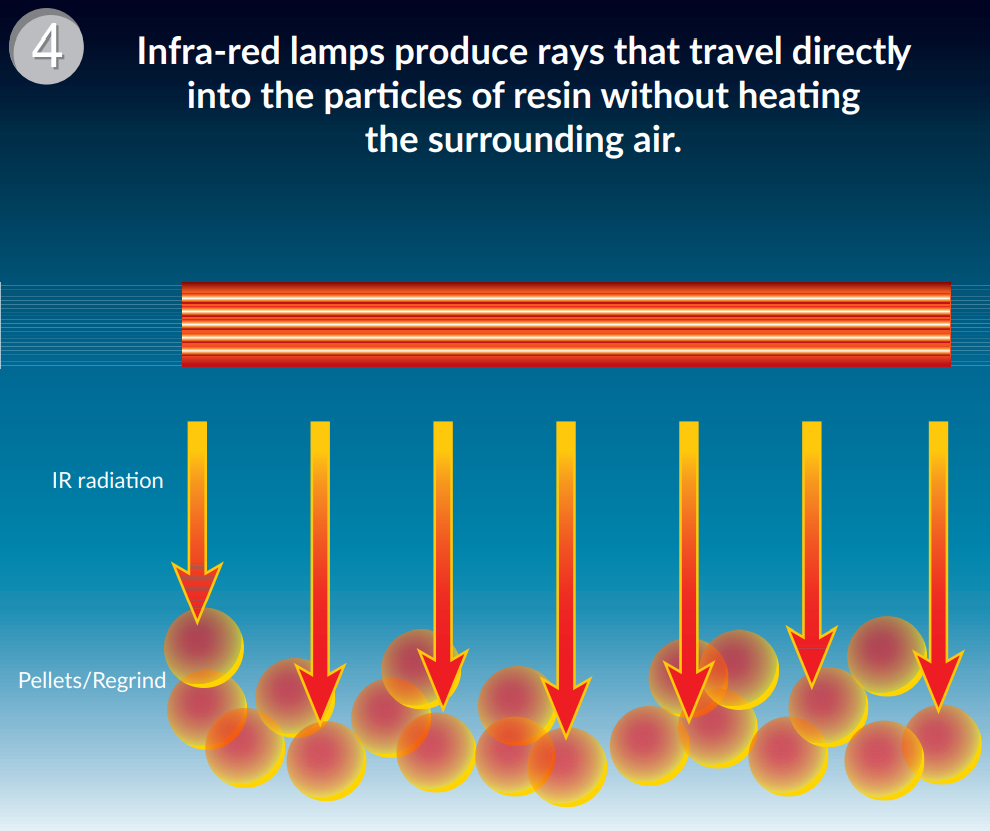

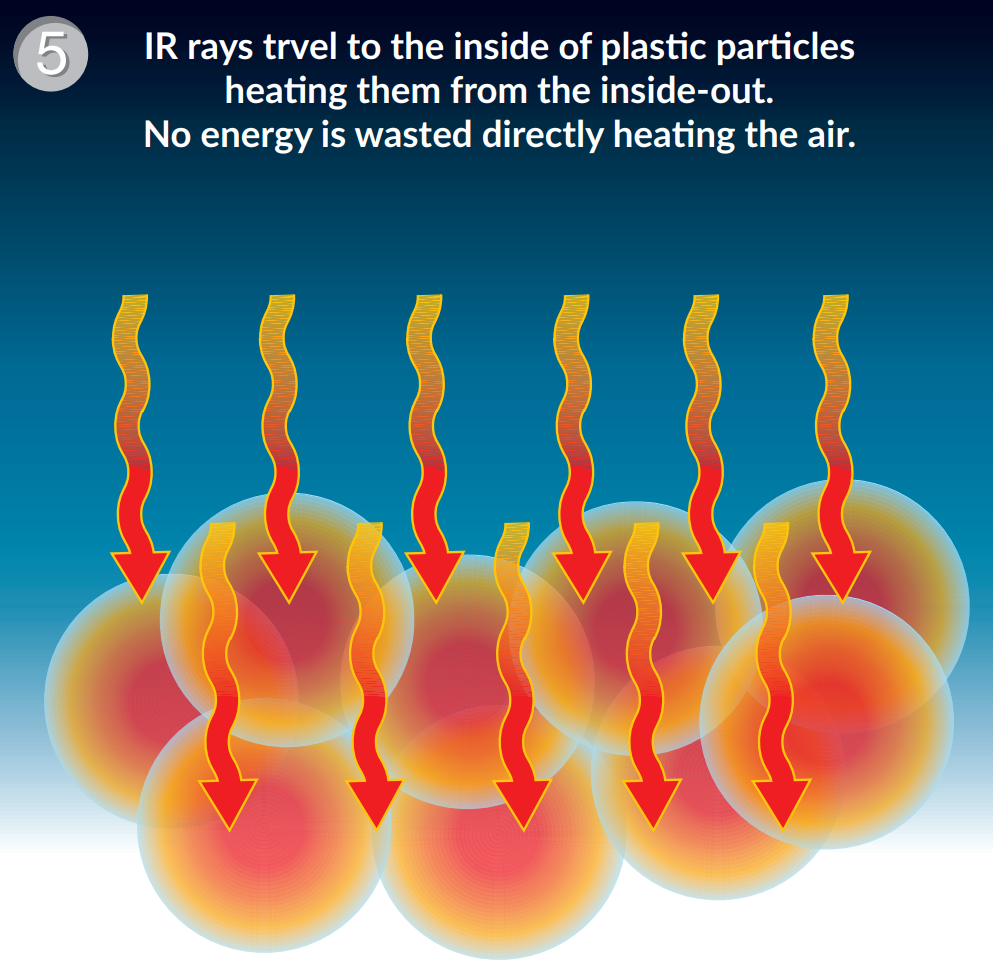

>> Reprocessing flakes a extruder yana rage IV saboda hydrolysis i kasancewar ruwa, kuma shi ya sa pre-bushewa zuwa iri-iri bushewa matakin da mu IRD System iya iyakance wannan rage. Bugu da kari,PET narkewar tube ba ya juya rawaya saboda lokacin bushewa ya ragu(Lokacin bushewa kawai yana buƙatar 15-20mins, danshi na ƙarshe zai iya zama ≤ 30ppm, amfani da makamashi ƙasa da 80W/KG/H)

>>Sai kuma ana raguwa da shear a cikin extruder saboda kayan da aka rigaya ya shiga cikin extruder a akai-akai”

>>Inganta kayan aikin PET Extruder

Ana iya samun haɓakar girma mai yawa ta 10 zuwa 20% a cikin IRD, yana haɓaka aikin ciyarwa a mashigar extruder sosai - yayin da saurin fitarwa ya kasance baya canzawa, akwai ingantaccen aikin cikawa akan dunƙule.

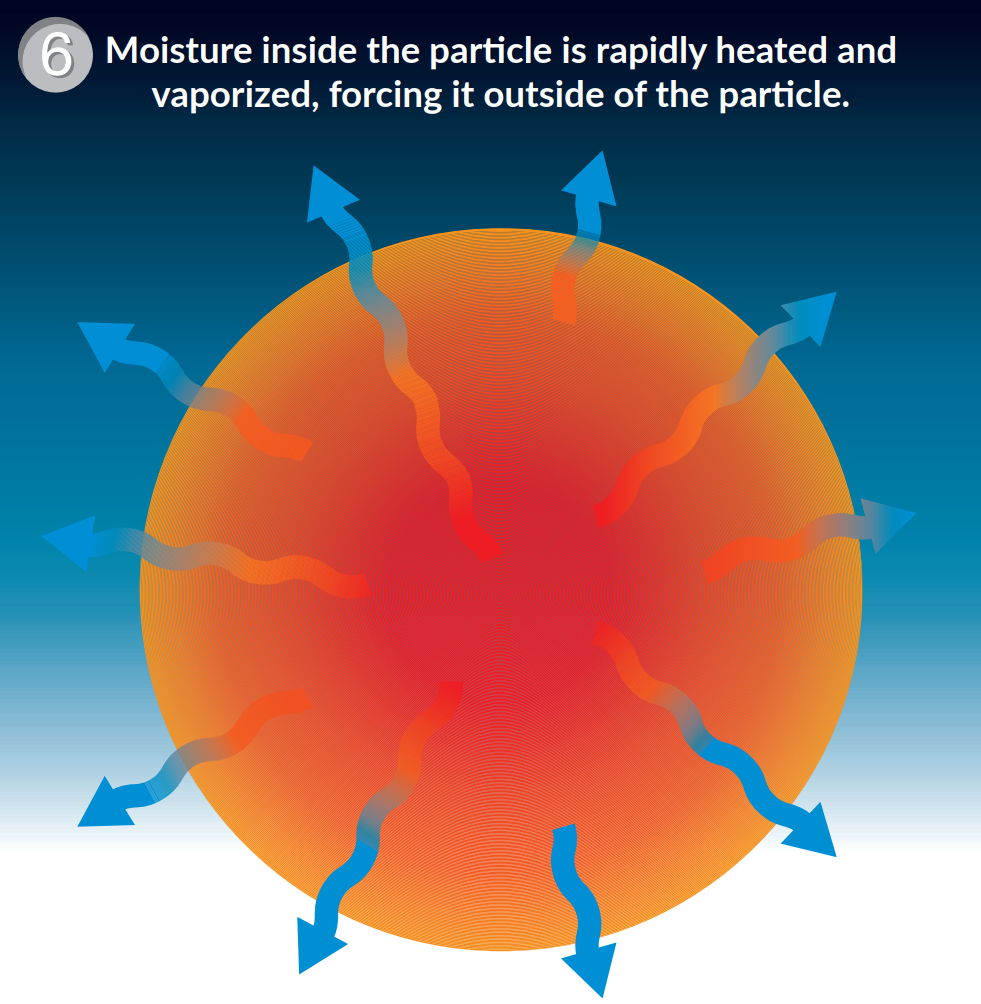

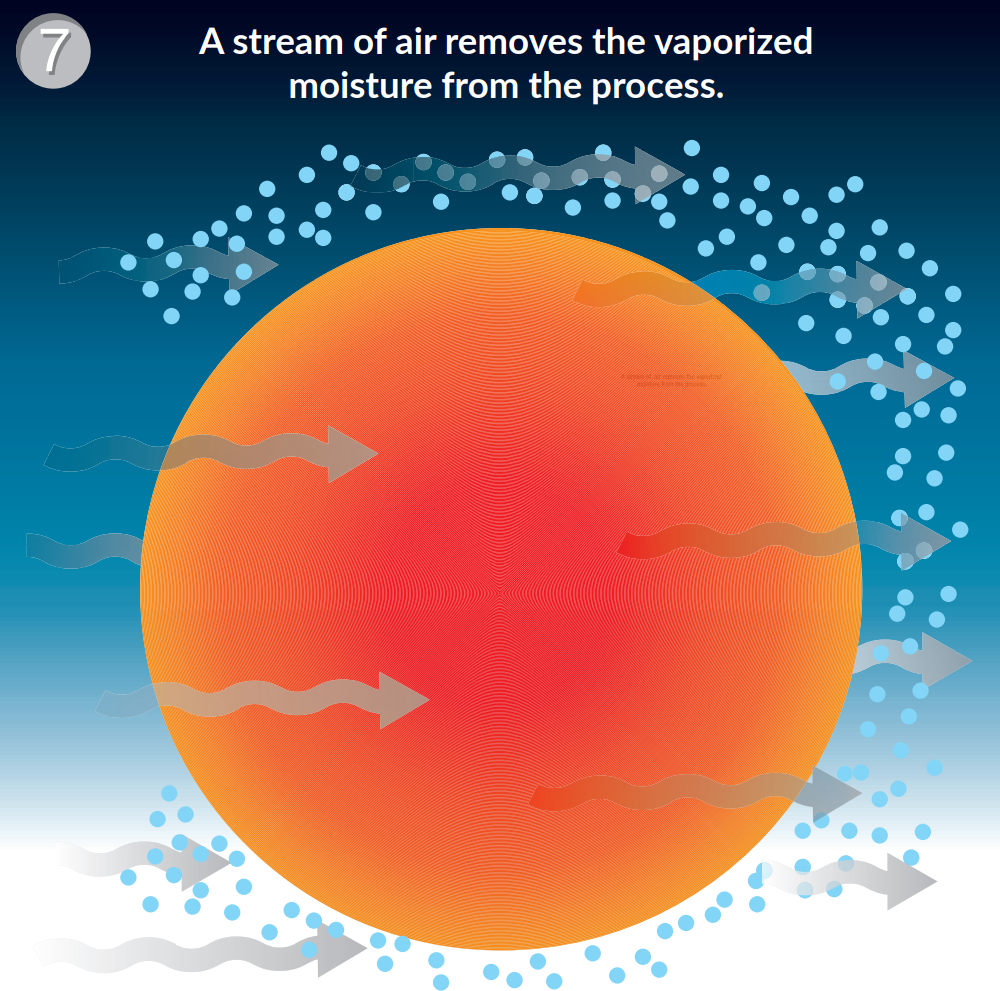

Ƙa'idar Aiki

Ribar da Muke Yi

※Ƙayyadaddun lalacewar hydrolytic na danko.

※ Hana haɓaka matakan AA don kayan tare da hulɗar abinci

※ Ƙara ƙarfin layin samarwa har zuwa 50%

※ Haɓakawa da sanya ingancin samfurin ya tsaya tsayin daka-- Daidaitacce kuma mai maimaita abun cikin shigar da danshi na kayan

→ Rage farashin samar da pellets na PET: Har zuwa 60% ƙarancin amfani da makamashi fiye da tsarin bushewa na al'ada

→ Farawa kai tsaye da sauri rufe --- Babu buƙatar pre-dumama

→ bushewa& crystallization za a sarrafa a mataki daya

→ Layin injin yana sanye da tsarin Siemens PLC tare da aikin ƙwaƙwalwar maɓalli ɗaya

→ Yana rufe yanki na ƙananan tsari mai sauƙi da sauƙi don aiki da kulawa

→ Zazzabi mai zaman kanta da saita lokacin bushewa

→ Babu rarrabuwar samfuran tare da nau'ikan girma daban-daban

→ Sauƙi mai tsabta da canza kayan

Inji Gudu a masana'antar Abokan ciniki

FAQ

Tambaya: Menene danshi na ƙarshe da za ku iya samu? Shin kuna da iyakancewa kan danshin farko na albarkatun ƙasa?

A: Danshi na ƙarshe za mu iya samun ≤30ppm (Ɗauki PET a matsayin misali). Danshi na farko zai iya zama 6000-15000ppm.

Q: Muna amfani da sau biyu a layi daya dunƙule extruding tare da injin degassing tsarin for PET Extrusion granulating line, za mu har yanzu bukatar yin amfani da pre-bushe?

A: Muna ba da shawarar amfani da Pre-bushe kafin extrusion. Yawancin lokaci irin wannan tsarin yana da ƙayyadaddun buƙatu akan farkon danshi na kayan PET. Kamar yadda muka sani PET wani nau'in abu ne wanda zai iya ɗaukar danshi daga yanayi wanda zai sa layin extrusion yayi aiki mara kyau. Don haka muna ba da shawarar amfani da pre-bushe kafin tsarin extrusion ku:

>> Ƙayyadaddun lalacewa na hydrolytic na danko

>>Hana haɓaka matakan AA don kayan tare da hulɗar abinci

>>Ƙara ƙarfin layin samarwa har zuwa 50%

>> Ingantawa da sanya ingancin samfurin ya tsaya tsayin daka-- Daidaitacce kuma mai maimaita abun ciki na kayan shigar da shi

Tambaya: Menene lokacin bayarwa na IRD ɗin ku?

A: Kwanaki 40 na aiki tun lokacin da muka sami kuɗin ku a asusun kamfanin mu.

Tambaya: Yaya game da shigar da IRD ɗin ku?

Kwarewar injiniya na iya taimaka maka shigar da tsarin IRD a masana'antar ku. Ko kuma za mu iya ba da sabis na jagora akan layi. Duk injin ɗin yana ɗaukar filogin jirgin sama, mai sauƙin haɗi.

Tambaya: Menene IRD za a iya nema?

A: Yana iya zama pre-bushe don

- PET/PLA/TPE Sheet extrusion inji line

- PET Bale madaurin yin inji line

- PET masterbatch crystallization da bushewa

- PETG Sheet extrusion line

- PET monofilament inji, PET monofilament extrusion line, PET monofilament ga tsintsiya.

- Injin yin fim na PLA/PET

- PBT, ABS / PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET (Bottleflakes, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA, PBAT, PPS da dai sauransu.

- Hanyoyin thermal donkau da sauran oligomeren da maras tabbas sassa.